RICHARD BURBIDGE FUSION STAIRS & FUSION STAIR PARTS FITTING GUIDE

|

|||||||||

|

The Fusion range of stair parts is manufactured by Richard Burbidge, with and . You can not buy Fusion stair parts directly from Richard Burbidge they can only be purchased from suppliers such as Pear Stairs. You can also find a range of stair parts. |

|||||||||

Richard Burbidge Fusion Fitting Guide |

|||||||||

|

The following instructions are for installing Fusion on to a closed string staircase. |

|||||||||

|

Fusion stair balustrading comprises a patented system of round newel posts and handrails connected together using a series of metal brackets. Spindles fix into place using brackets designed to adjust to suit staircase pitches between 38° and 45°. When installing Richard Burbidge Fusion remember at all times that when you are assembling a pre-finished product extra care should be taken to avoid damaging the finish. All finishes are carefully checked prior to leaving the factory and are designed to withstand most types of normal use, however, it is possible to damage these with sharp tools. Please check all components carefully prior to installation for any damage to the surface. Please note we cannot be held responsible for any damage once installation has been commenced. Fusion carries design registration and has patent pending. Genuine Fusion components carry the Richard Burbidge dovetail logo. Only genuine components have been independently tested to guarantee conformity to current UK building regulations. Fusion is designed for use in domestic situations and will fit closed string staircases with pitches between 38° and 45° and handrail heights of 900mm stairs and 900mm landings. Fusion is tested to UK strength requirements of 0.36kN/m. Tools Required - Fusion Tool Kit. |

|

Tool Kit To make things easier we offer a toolkit with all of the necessary and specific tools required to install Fusion balustrading.

|

|

|

To buy this Fusion tool kit, |

|

|

Fusion is manufactured to exacting tolerances, however, as wood is a natural material some expansion and shrinkage of the timber components can occur. If the newels and rails are slightly too big for the connectors, gently sand/shave the components to allow for a tight fit, being careful to only rework the area of the timber component that will be concealed by the metal connector. Alternatively, if the timber component is loose in the connector, a rigid fix can be achieved using a proprietary gap filling adhesive. |

|

Assembly Staircase Balustrading. |

|

|

Fusion will fit most staircase configurations. Fusion can be fitted to either existing or new newel bases. To use existing newel bases, these must be fixed centrally to the staircase string and the front face of the riser concerned. |

|

|

|

|

|

Before removing existing newel bases, check that they are non-supporting or do not form a structural part of the staircase design. When using Fusion your existing newel base must be a minimum of 82mm x 82mm. If less, face/build up existing bases using a suitable facing material.These instructions are for a straight flight with return landing. |

|

Existing Bases. |

|

|

Fusion stair parts use pre-cut spindles, and all cut-off points are referenced from the top of the baserail upwards. |

|

|

|

|

The system is designed to automatically compensate for any slight inaccuracies in cutting off the existing newel post. Before newel bases can be set to the correct height the baserail must be installed. |

|

Bottom Newel Base. |

|

|

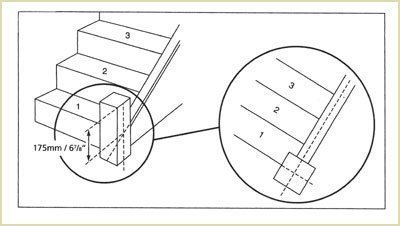

From the line representing the top edge of the baserail mark a line upwards through the centre point of the newel base and where the two lines intersect measure up 175mm. |

|

|

|

Top Newel Base. |

|

|

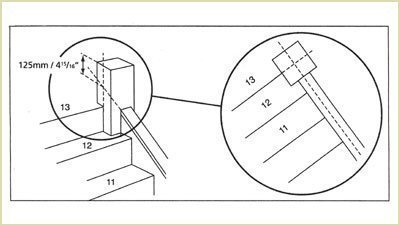

The top newel base should be marked in the same way at the bottom, but the height should be set at least 125mm. |

|

|

|

|

It is important that existing newel bases are cut off squarely so that the newel posts are perfectly vertical. Once the bases are cut, trial fit the newel posts and check with a spirit level. The top of the bases can be sanded level if required. This will reduce the height of the bases slightly but the newel assemblies can compensate for this within the connectors. Once the bases have been levelled they can be chamfered to provide a more pleasing finish. |

|

Newel Base Connectors. |

|

|

Newel base connectors can now be fixed to the newel base using the stud barrel nut supplied. |

|

|

Staircase Newel Base Connector - MMNC |

|

|

|

|

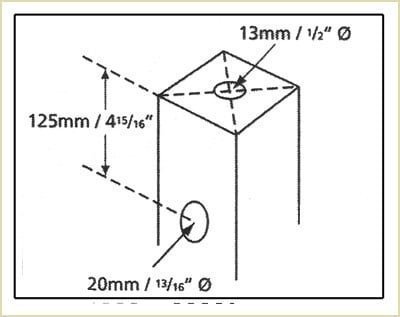

From the top of the newel base on the centre line previously marked, measure down 125mm. Using a 20mm spade bit, drill a hole to the depth of 20mm beyond the centre point of the newel base. |

|

|

|

On the top of the newel base find the centre by drawing two diagonal lines from corner to corner. Using a 13mm spade bit drill to a depth of 125mm. |

|

Please Note - All drill operations should be straight and accurate. |

|

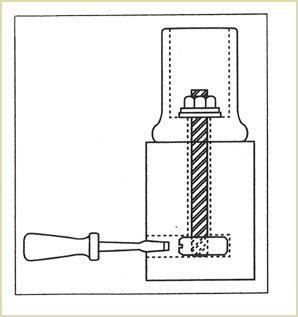

Assemble the newel base connector to the newel base by locating the barrel nut and fully inserting the fixing stud. |

|

|

Place the newel base connector over the fixing stud and tighten nuts using the 19mm socket/box spanner making sure that the connectors are positioned as illustrated. Please Note - In most cases when tightening the base connector to the existing bases, the retaining ring on the underside of the connector should pull into the newel base. However depending on the timber type it may be necessary to disassemble the connector and chisel a clearance ring of approximately 3mm wide by 5mm deep allowing the newel base connector to sit flush. Cut the bottom newel post to a length of 525mm and drill a 25mm diameter clearance hole at a depth of 25mm to the underside of the post to allow it to fit over the stud assembly. |

|

|

Fix post to the connector using screws provided making sure the post is fully inserted. Fix the top post in the same manner but do not cut the top post at this stage. Please Note - To mark the position of the clearance hole in the newel post, place newel into base connector, knock gently and then remove post |

Fixing Top and Bottom Connectors and Handrails. |

|

Fixing the connectors and handrails is best done by two people. To establish the correct angles of connectors and lengths of handrail, you will need to assemble two spindles. Fit the brackets to the ends of the staircase spindles by inserting the screws supplied. |

|

|

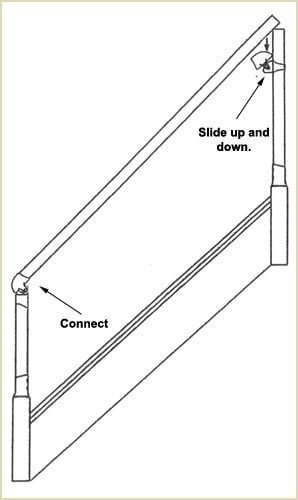

The bottom connector and top connector are a two part assembly. The complete top post connector slides over the top newel post (do not permanently fix at this stage). The bottom post connector (only the part that slides over bottom newel) can be fixed to the bottom newel. |

|

|

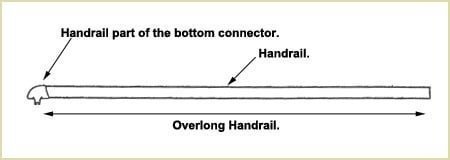

The handrail part of the bottom connector should now be attached to the overlong handrail. |

|

|

Attach this bottom connector to the bottom newel. Adjust the height of the top connector by sliding up and down the top post. The handrail part of the bottom connector should now be attached to the overlong handrail. |

|

|

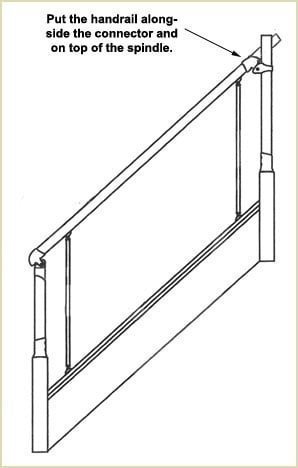

Put the handrail alongside the top connector and on top of the spindle. Mark the position of the top connector to the newel post using a pencil and the overlong handrail to the side of the top connector, mark and cut the handrail to the required length. |

|

|

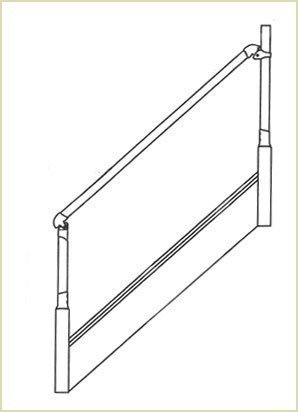

Fit the top post connector in place by setting to the previously marked pencil line and secure the newel post part of the connector using the screws supplied. It is important that this connector is fixed so that it is in line with the bottom newel. Fix the handrail connectors to the ends of the handrail and then fix this assembly to all newel post connectors checking that everything is vertical and parallel before securing all connector bolts, nuts and screws. |

|

Fitting Fusion Spindles |

|

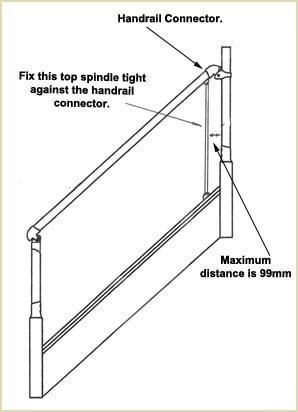

You are now ready to fix the top and bottom spindles . The top spindle must be fixed so that it is tight against the handrail connector so as to conform to building regulations (i.e. no opening greater than 99mm). |

|

|

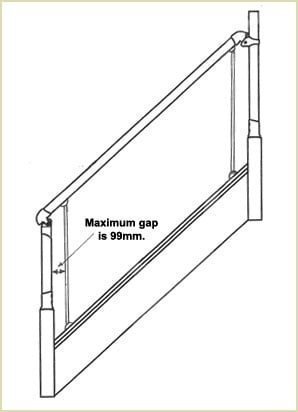

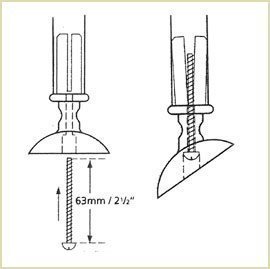

Position the spindle between the handrail and baserail check for vertical and mark the position of the spindle bracket to the baserail with a pencil. Remove the spindle and fix the baserail to the staircase string using the 45mm No. 8 countersunk screw. The screw fixing the baserail to the staircase string should be positioned so that it does not interfere with the spindle bracket fixing screws. Reposition the spindle and fix to the handrail and baserail using the screws. supplied. Fix the bottom spindle and space so that the gap between the spindle and the newel post is no greater than 99mm. |

|

|

To space the remaining spindles evenly up the stairs measure the distance between the bottom and top spindles already installed and divide by 148.5mm. Round the answer up to the next whole number and divide this whole number back into your original measurement to give an exact spacing. |

|

|

Example: 2159mm between bottom and top spacing marks divided by 148.5mm = 14.45mm rounded up to 15mm. 2159mm ÷ 15 = 143.9mm spacing measurement. |

|

Fix all remaining spindle brackets to spindles using the screws supplied. Mark the spacing between spindles on the baserail either using a pencil and tape measure or by marking and cutting a piece of timber to the required length. Fix the assembled brackets and spindles to the baserail. The top of all the spindles can now be fixed to the underside of the handrail using a spirit level to check for vertical. |

|

Please Note - If you have a particularly short flight of stairs you may need to re-space the balusters to provide a more pleasing effect, remembering at all times to space them no more than 99mm apart. |

Assembling Horizontal/Landing Spindles. |

|

The maximum distance we recommend between landing newels and wall connectors is 2400mm. For landings exceeding this recommendation, an additional newel should be used for stability on the mid-span of the landing. |

|

|

You can come off a top newel at 90° as below. |

|

|

Using standard Fusion components you will require a minimum of 120mm measured from the centre of the landing baserail for stairs with landings set back from the main flight of stairs, see below. |

|

Using standard Fusion components you will require a minimum of 120mm measured from the centre of the landing baserail for stairs with landings set back from the main flight of stairs, see below. |

|

|

Place an off-cut of handrail loosely into the landing connector. Position the one assembled landing spindle onto the baserail and place the handrail and connector on top of this spindle and to the side of the top newel to establish the required height of the post, Mark and cut to suit. |

|

|

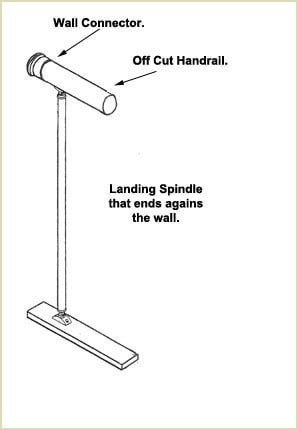

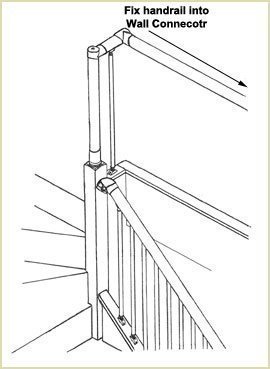

Where the landing spindle ends against the wall, mark the position of the wall connector on the wall by placing an assembled landing spindle and wall connector to off-cuts of the handrail. Mark the position of the wall connector to the wall and drill and plug to suit. |

|

|

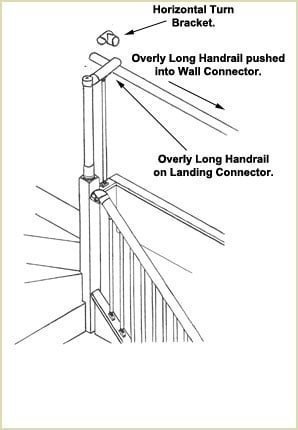

Place an off-cut of the handrail to the landing connector and position on the top newel. Push the landing handrail into the wall connector and check the horizontal turn to where the two handrails meet to establish lengths of cut. Mark and cut the handrails to the required length. |

|

|

Reposition the landing handrail to the wall connector and fix horizontal turn to the other end of this rail. Fix the short return length of handrail onto the other leg of the horizontal turn and the landing connector and position over the top newel post. Please Note - Before screwing all connectors to rails and top post, we recommend a final check. |

|

|

To calculate the exact number of landing spindles either divide the total length by 117mm, which will give a gap of approximately 98mm, or alternatively you may find it aesthetically more pleasing to space the landing spindles so that they are in line with the staircase spindles. Assemble all spindle brackets to the ends of the landing spindles by inserting the relevant fixing screw into the underside of the brackets and tighten. |

|

|

Fix all bottom spindle brackets to the baserail using 30mm No. 6 screws and finally secure the top spindle brackets to the underside of the landing handrail using 30mm No. 6 screws checking for vertical with a spirit level. See drawing below for finished assembly. |

|

|

Buying your Parts should be easy with Pear Stairs. We are pleased to be a main supplier of the FUSION range, if you have any questions regarding FUSION® don't hesitate to phone us about your choice. We are a very friendly company, phone Pear Stairs on 01938 553311. |